DASAN’s Technique

DASAN possess integrated technical expertise spanning development, design, manufacturing, and systems.

Based on this proprietary technology, we manufacture customized products that meet customers' specific needs.

-

Slow Pumping (DGV/DPV)

Implementation of soft pumping between the chamber and

the pump to prevent pump damage.

-

Heating Impact _ Powder Protection (DPV)

Uniform temperature distribution delays

powder adhesion in pipes and valves

-

Fastest Speed _ Close (DGV/DPV)

In an emergency, valve closure is implemented within

0.3 seconds to prevent contamination inside the chamber.

-

Low-Vibration&Noise (DPV/DIV)

Minimizing vibration and noise during valve opening and closing

using special materials and proprietary sealing technology.

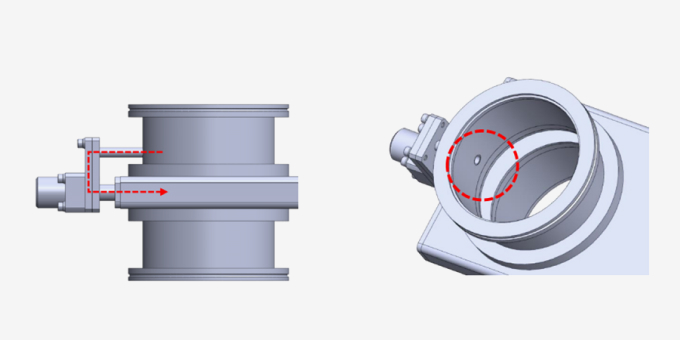

Slow Pumping (DGV/DPV)

Due to the pressure difference between the facility (chamber) and the pump during the manufacturing process, the pressure between the top (facility) and bottom (pump) is equalized before opening or closing the valve to prevent damage to both the valve and the pump.

- Prevent Pump Damage Adjustable Slow Pumping Speed

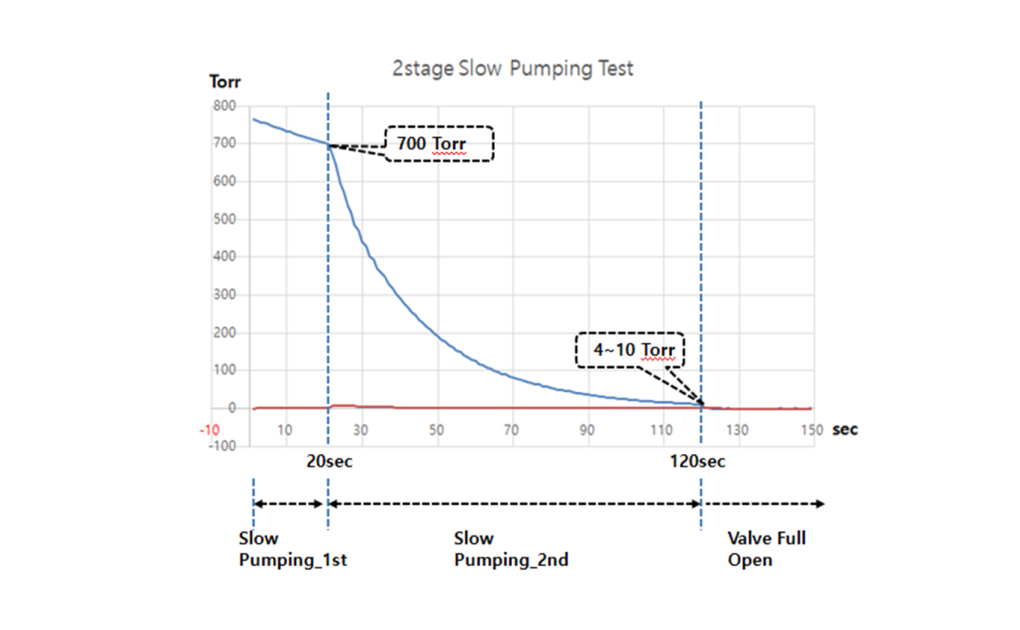

- 1st stage20 seconds at 700-680 Torr (approximately 685 Torr)

- 2nd stage100 seconds below 5 Torr (approximately 4.3 Torr)

Pressure changes over time during slow pumping

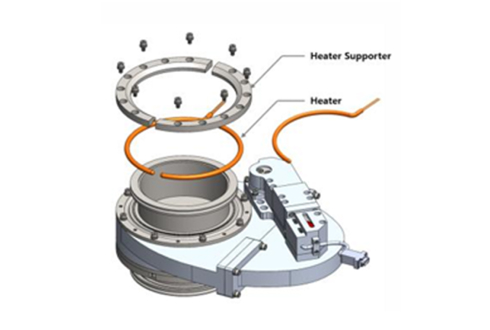

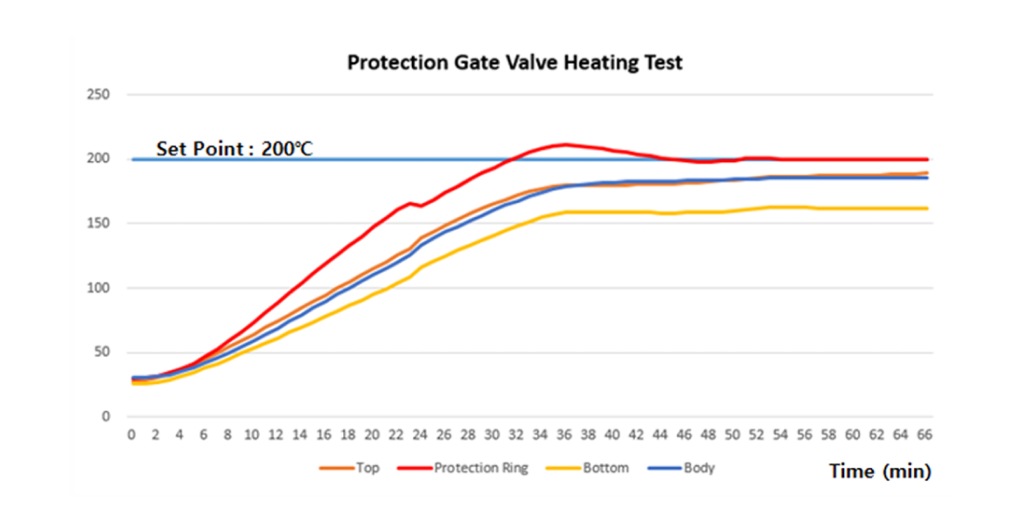

Heating Impact Powder Protection (DPV)

Temperature Ramping up Time : Set Temperature 200℃, 30~40mininutes

The combination of an alumininum body composition and upper and

lower Cartridge Heater maximizes the heating impact inside and outside the valve

The design can delay the deposition of the powder due to the internal heating impact effect,

which cannot be expected with a heating jacket

Insertion Heater

- Time (min)

- Start

- 3

- 5

- 8

- 13

- 20

- 29

- Time (min)

- Time (℃)

- Start

- 3

- 5

- 8

- 13

- 20

- 29

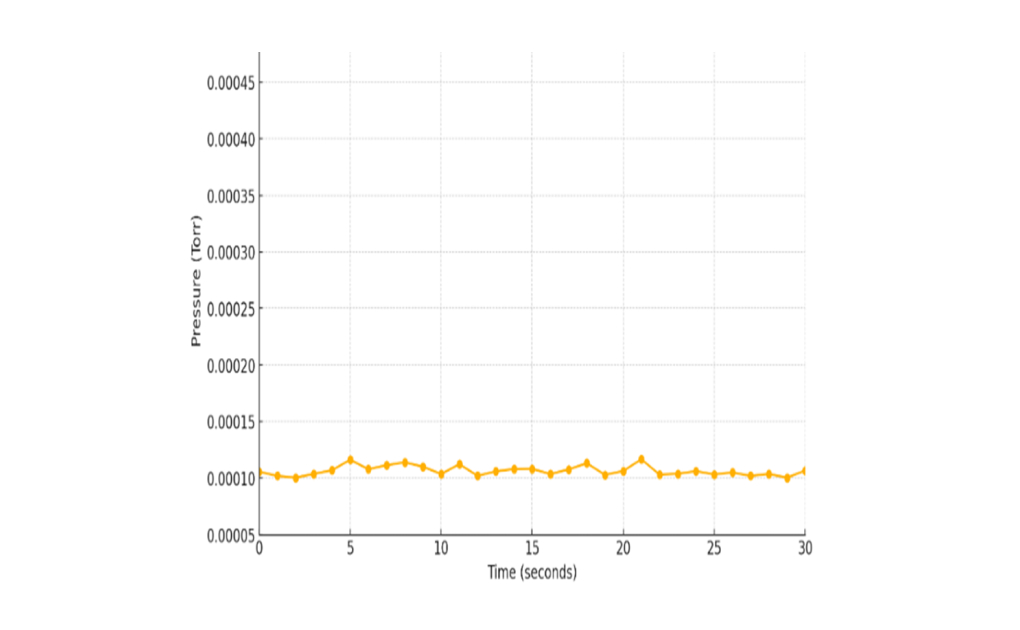

Fastest Speed Close (DGV/DPV)

In an emergency, the valve can be closed quickly to minimize damage to semiconductor equipment and pumps.

In an emergency, the valve can close within 0.3 seconds.

As a result, the back pressure is expected to be within 0.0001 Torr, minimizing secondary damage to the pump and equipment.

Change in base pressure after pressing the EMO (Emergency Off) button

Low-Vibration

&Noise (DPV/DIV)

We enhanced the product's quality by minimizing vibration and noise.

Our company uses special sealing technology in Pendulum valve (with special materials) and i-Motion valve to produce low vibration and noise during valve opening and closing. This technology ensures the maintenance of an ultra-high vacuum state, provides stable vacuum retention, and focuses on minimizing performance degradation and reducing failure rates over extended periods of operation.

Additionally, the low vibration significantly helps prevent particle dispersion inside the pipes and valves during on/off operations. Our valves are also highly compatible with various deposition equipment and processes, making integration easy during equipment upgrades and changes.